Filament Quality and Why It Matters

There are many factors that determine how well a 3D printer prints. While many of them involve tuning and tweaking the actual 3D printer itself, the filament you print with may be one of the most important determining factors in a quality print. Filament is one of those parameters that is often overlooked because, for the most part, it usually looks fine on the exterior. However, just under the surface, things like air pockets and debris could be waiting to ruin your printing experience.

Regardless of what type of filament you are printing with, using filament of known good quality is paramount to having a successful print. A simple Google search of the terms "Clogged Nozzle" or "3D Printer Extruder Jam" will yield dozens of pages of results where people have experienced a jam or clogged nozzle on their 3D printer. The majority of these cases usually turn out to be the result of someone using poor quality filament from China that they bought on eBay. That's not to say that all 3D printer filament from China is bad, but history has proven that most of it is not reliable.

The problem with cheap filament is that it is usually extruded at lighter tolerances and with materials of questionable origin. For 1.75mm and 3mm filament, the outer diameter should not exceed +/- 0.1mm, with 0.05mm being ideal. Anything over these tolerances could jam the extruder of the nozzle's inner chamber, which is machined to exacting tolerances. Additionally, the use of out of tolerance filament will cause over or under extrusion, which is the major cause of blobbing and voids in the finished print. This is because the slicing software used to prepare the .stl for printing calculates exactly how fast to extrude based on a constant filament size.

As I mentioned above, cheap filament can clog or jam your extruder and affect the outcome of the print if low-quality or "dirty" raw materials are used in its manufacture. The term "dirty raw materials" is what I use to describe raw materials that have been recycled with foreign or "non-pure" plastic mixed into the batch. These foreign materials can range from recycled ABS or PLA plastic that happens to have a different plastic part welded to it, or even bits and pieces of foreign objects mixed in such as sand, metal filings, or, in extreme cases, paper and wood bits. While not a "green" method of doing things, I like to use 3D printing filament from manufacturers that use as many virgin materials as possible.

Another issue with cheap filament is the inclusion of air bubbles into the filament during the manufacturing process. These tiny bubbles of air and moisture expand rapidly when heated to the temperatures seen in a 3D Printer's nozzle, and the result is a loud pop or bang that occurs when the air pocket reaches the nozzle orifice. This causes both blobbing and voids in the print surface, which reduces overall print quality. Cheap filament is riddled with these tiny air bubbles, and anyone who has ever printed with cheap filament knows all too well about how loud these pops can be.

One final reality of cheap filament is the lack of deep saturated colors. To save money, manufactures of cheap filament cut the amount of color pigment during manufacturing. This causes everything from washed out colors to blotchy and even transparent layers in prints. While not the main reason you should consider investing in good quality filament, color consistency and richness are definitely an added bonus that comes with quality filament.

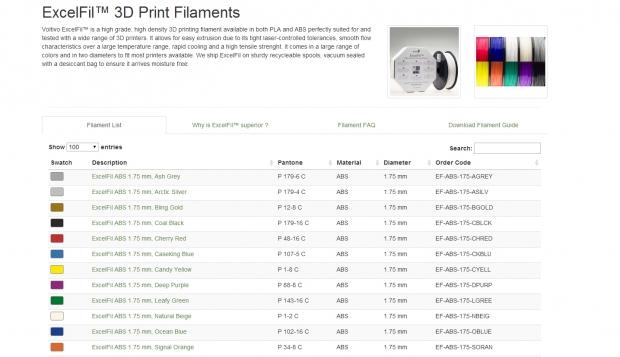

Over the last month and a half, I have had the pleasure of printing with some of the highest-quality 3D printing filament made, and, with how pleased I am with this filament, to say that I am impressed is an understatement. I am of course talking about Voltivo's ExcelFil line of ABS and PLA filaments. ExcelFil comes in both 1.75mm and 3mm sizes and is available in a rainbow of extremely rich and vibrant colors. Most importantly, ExcelFil is manufactured from the highest quality material available.

Voltivo says that its ExcelFil filament is manufactured using precision machines that utilize high-precision lasers to measure the extrusion diameter many times every second for a more consistent diameter. The company also says that its plastic is manufactured from high-purity raw materials and never uses any recycled or tainted raw materials in the production of ExcelFil. Furthermore, Voltivo goes the extra mile and prints samples from every batch of filament to ensure that its customers have nothing but the best 3D printing experience possible when using its filament. Pigment saturation is also top priority for Voltivo, and its ExcelFil filament features more pigment per kilogram than other 3D printing filament manufacturers on the market.

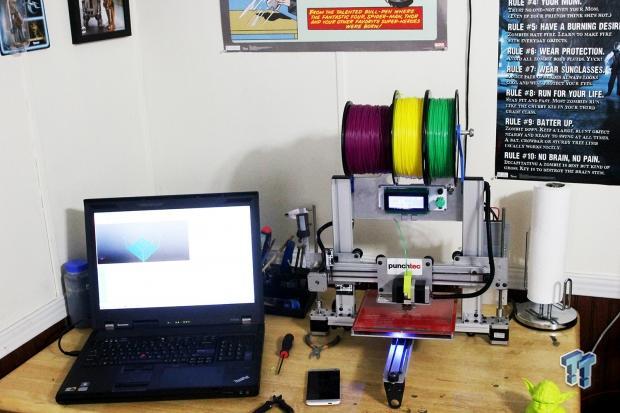

Over the past several years, I have used dozens of different filaments from manufacturers around the world; when I received my first shipment of ExcelFil, I could instantly tell that it was some of the good stuff. Right out of the box, I noticed that the green, red, and yellow ExcelFil I received was much brighter and vibrant than any filament I have used in the past, with the exception of some production samples I received from a company out of Germany several years ago.

Over the last several weeks, I have printed about a pound of PLA and a pound of ABS from my ExcelFil samples, and not once have I experienced an extruder jam or nozzle clog. I have been taking measurements of the filament's diameter randomly, and the ExcelFil is spot on.

Unlike most other 3D printer filament manufactures, Voltivo lists out the technical specifications, temperature recommendations, and other useful information all on a handy support site that includes a downloadable filament guide that explains the benefits of using high-quality filament. Voltivo's ExcelFil contains roughly 345 meters of 1.75mm PLA per spool, while 411 meters of 1.75mm ABS is wound onto each one kilogram spool. For 3mm PLA and ABS, one kilogram spools contain about 117 meters and 140 meters of filament respectively. The variance in lengths between each plastic type is due to density differences between ABS and PLA.

Filament Quality and Why It Matters Cont.

I often get asked how many objects I can print from a single spool, and I usually have a hard time answering as it varies greatly with my prints due to my tendency to change up infill levels for each print based on its use, design, and size. While reading over Voltivo's website, I found a handy answer for this question. On average, an iPhone cover takes about 1.14 meters to print using 3mm PLA. Based on the numbers above, I can print about 100 iPhone covers from a single 1kg spool of 3mm filament. For me, it varies depending on what I print. I have had spools last me several months because I am printing a lot of small items with downtime in between, and I have burned through an entire spool in just a few days because I printed a few very large and dense objects.

Like I mentioned earlier, the depth of documentation that Voltivo has provided for its customers is immense, and things like recommended extruder temperature per color of filament is a very big deal for me. Each color of plastic has its own "sweet spot" that it likes to print at. This is because 3D printers do not print with molten plastic, but rather they print with plastic that is heated to what is known as the "Glass Transition Phase" (GTP). The GTP is the point just before plastic becomes molten and runny, and pigments in 3D printing filament greatly affect the plastic's GTP.

Since the optimum printing temperature varies from color to color, lots of time and plastic is usually wasted through trial and error when trying to find this sweet spot on new plastic. Voltivo has made this process quick and painless by listing out the optimum printing temperature per color for PLA and ABS of both sizes.

While I prefer to print in ABS, PLA is quickly winning me over due to its lower temperature and lack of need for a bonding agent to keep it stuck to the printing surface. My apprehension to PLA goes back a few years to a bad experience I had with the plastic. At the time, PLA for 3D printing was still in its infancy, and I happened to get a very bad batch of filament samples from a company that was seeking my evaluation of the product. I could not get it to stick to anything, and it repeatedly clogged a 0.5mm nozzle. I have printed from several different spools of ExcelFil in different colors and have not once experienced a jam or clogged nozzle. On the other hand, the spool of cheap purple PLA I purchased off of eBay has forced me to tear down the extruder on my Punchtec Ord Bot Hadron several times.

It has been quite a while since I have had an extruder jam with ABS, which is my preferred plastic to print in. Therefore, I always purchase high-quality filament of known origin. The ABS ExcelFil was no exception either; it prints like a dream, and the colors are deep, rich, and smooth when extruded. I find that I need less tension, too, for my extruder to get a good grip on the filament, which is usually an issue for other brands of ABS. On some, I have to turn the knobs on my Lulzbot AO-100 almost all the way to get a good grip.

Finally, Voltivo impressed me with the extra mile it went in designing the packaging for its ExcelFil filament. Usually spools of filament come packaged in a thick plastic bag that has been vacuum sealed with a small desiccant pack tossed in. The spool is then tossed into a box with several other items or spools of plastic and shipped to your home. Often times, the bag the filament is sealed in springs a leak and allows air to once again fill the bag. This lets moisture in, which the plastic quickly begins absorbing, which causes popping and bad prints. ExcelFil is sealed in the same thick bag with a desiccant pack, with each spool then being placed in its own box for protection. This extra step ensures that the plastic vacuum sealed bag is not damaged and the filament arrives nice and dry.

As someone who has seen and used hundreds of pounds of 3D printing filament over the last several years, I can honestly say that Voltivo's ExcelFil is at the top of my list for best 3D printing filament. I like ExcelFil so much that I have adopted it as the only filament that I will use in my 3D printer reviews here at TweakTown, unless, of course, the printer uses a proprietary filament cartridge such as the Da Vinci from XYZprinting. Using a high-quality filament that is consistently good across all colors is a very big deal when it comes to benchmarking 3D printers, and, with Voltivo, I know that I am getting the best of the best.

United

States: Find other tech and computer products like this

over at

United

States: Find other tech and computer products like this

over at  United

Kingdom: Find other tech and computer products like this

over at

United

Kingdom: Find other tech and computer products like this

over at  Australia:

Find other tech and computer products like this over at

Australia:

Find other tech and computer products like this over at  Canada:

Find other tech and computer products like this over at

Canada:

Find other tech and computer products like this over at  Deutschland:

Finde andere Technik- und Computerprodukte wie dieses auf

Deutschland:

Finde andere Technik- und Computerprodukte wie dieses auf