Introduction

3D printing is all the rage at the moment. The ability to design or download an object and watch it form in front of your eyes is a very appealing thing to a lot of people.

Up until a few years ago, printing physical objects in the third dimension was something that was just out of reach for the average consumer, with entry-level commercial machines costing tens of thousands of dollars. One day in 2005 a professor at the University of Bath in the UK decided to change the 3D printing world forever.

Dr. Adrian Bowyer, a senior lecturer in mechanical engineering at the University of Bath decided to tackle the problem of an affordable and hobby sized 3D printer. He began the RepRap project which quickly caught fire and spread across the internet. Now eight years later there are a multitude of hobbyist level 3D printers on the market and each comes with its own unique set of pros and cons.

In this guide I am going to attempt to help you make sense of it all and hopefully guide you towards purchasing the best 3D printer that suits your needs. For the sake of simplicity, I am only going to focus on fused filament; additive deposition based 3D printers as they are the most popular style in the hobbyist market at the moment.

Before we get started we need to determine what kind of "Maker" are you? On the next page we will cover the different ways you can obtain a 3D printer of your own. Let's get started!

Different types of 3D Printing Kits

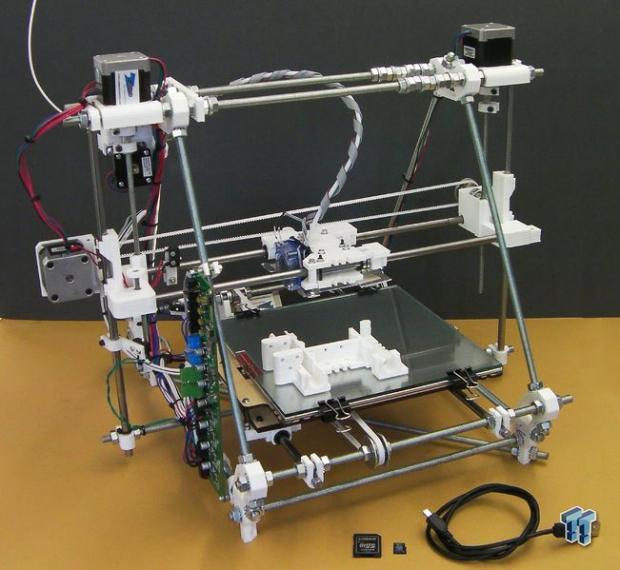

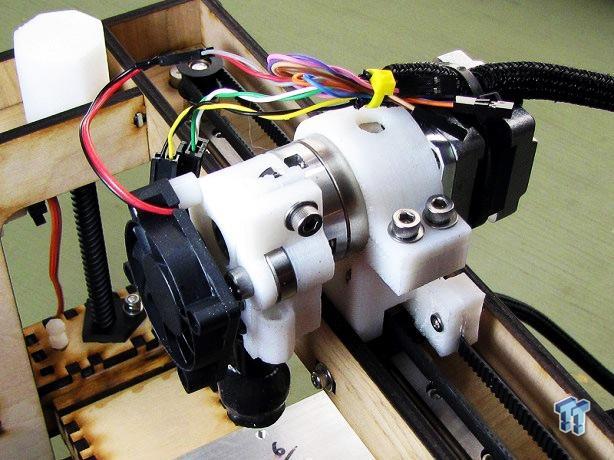

Scratch Built 3D Printer - Are you the DIY type who prefers to build things from scratch? If so, then you might consider going to DIY RepRap route. While it is up in the air if this method will actually save you any money, there is something to be said for building your own 3D printer from scratch. You become very intimate with the printer and will know every nut, bolt and quirk it has by the time you are successfully printing.

Unless you are mechanically inclined and very handy with building things, I would avoid this method as sourcing and modifying parts to fit can be a bit of a task for beginners. Once built you will need to spend hours configuring, adjusting, and calibrating things, before you are printing at an acceptable level of quality. The image above depicts a RepRap Mendel that was built from scratch.

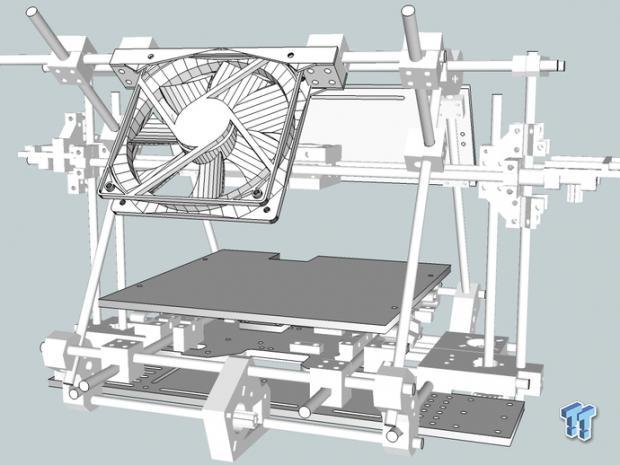

Kit Built 3D Printer - If you would still like to save some money, but not have to deal with the hassle of sourcing parts and modifying them to fit together, then maybe a kit is the way for you. Many manufacturers sell kits with "easy-to-assemble" instructions included. You still must be somewhat mechanically inclined and able to understand basic geometry. Many of these kits come with the electronics already built, but there are a few that require you to break out a soldering iron and populate the PCBs. If soldering is not your bag, then I would definitely avoid a kit that requires soldering.

Like a scratch build, you will need to spend hours adjusting, calibrating, and configuring things before your machine is printing at a good level of quality. The image above is the typical RepRap Prusa Mendel kit you will find for sale around the web.

Preassembled 3D Printer - These machines are ready to print out of the box and usually require very little tuning to print at high quality levels. Be prepared to pay a premium for an assembled and tuned printer, though. The advantage with these printers is that you can often times be up and printing within thirty minutes of opening the box. The disadvantage is that you did not assemble the printer yourself and as so, you have no clue what everything does.

So when something breaks, (and it will) you are almost always left in the dark and must turn to experienced printer builders for advice and guidance on what went wrong and how to fix it. The Lulzbot AO-101 pictured above is one of the high-end RepRap Mendel Max based 3D printers on the market today.

Frame Types

Most 3D printers on the market today are built around designs and technology that is derived from the RepRap project. This being so, there are a few main components in every fused filament based 3D printer that we need to look at. Below is a quick breakdown of each and what to look for when making your decision on which printer to purchase.

Each 3D printer has its own frame that its manufacturer considers superior to others for whatever reason. When choosing a 3D printer you need to pay close attention to what the frame is made of and what style it is based off of. For simplicity I am going to categorize the most common frames into four categories.

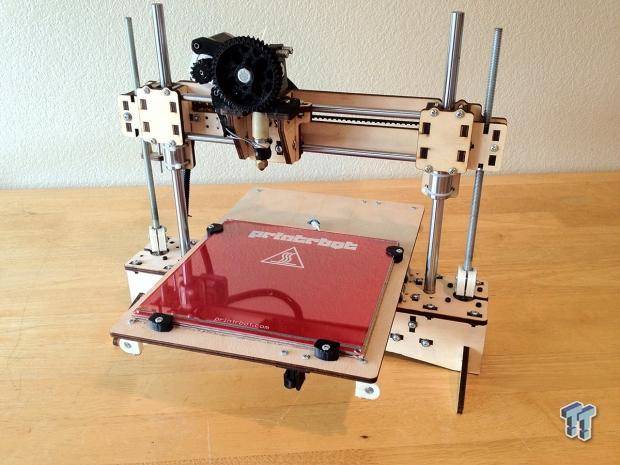

Open Air Style - This style frame can be found on some of the cheaper kits that utilize as few parts as possible to keep the cost down. These usually make very good entry level printers where frame rigidity is not a concern. One of the most popular open frame designs is the PrintrBot line of 3D printers.

Box Style - This was the most popular style for hobbyist grade 3D printers for a while and still remains up there with the prefabricated printers being sold. Their advantage is that they are quite portable, and offer a rigid frame if properly assembled. Their major disadvantage is that they are incredibly frustrating to work on and service. Makerbot popularized this style with their CupCake, Thing o Matic and Replicator 3D printers.

RepRap Mendel Style - This style is by far the most popular style amongst scratch builders and kit makers alike because there is a plethora of information available as well as an entire IRC channel that is quite active with those willing to help you get your printer up and running. Mendel's are based on a wedge design that is constructed from printed parts and threaded rod. The open design allows for very easy access, tuning and maintenance. The only flaw that I can find is that inexperienced users may have trouble getting all the threaded rods to match up perfectly. The current popular model is the Prusa Mendel variant that is cheaper and easier to assemble.

RepRap Mendel Max Style - Based off of a Prusa Mendel, the Mendel Max design is in my opinion the best out of the bunch. Its frame is constructed out of 20mm aluminum extrusions which are connected together by printed connector plates. This makes for a very solid and very strong construction which can easily support the weight of a man standing on top. The Mendel Max is the favorite of high-end kit builders as well as manufacturers who offer prebuilt machines. My personal printer, a Lulzbot AO-100, is a Mendel Max based machine and the only flaw I have found is that without rubber feet, the machine will move around a hard toped surface.

Extruder Types

The extruder is the heart and soul of your 3D printer and as such, close attention should be paid to its design, serviceability and ease of cleaning. Other important features to consider is what drive system does it use? Does it use a stepper motor or a dc motor to feed the filament?

Finally you need to take into consideration what type of hot end it uses as some are more prone to failure than others. I would only consider a printer that used a stepper motor to drive the filament and a hot end that offered easily changeable nozzles so you can fine tune your layer height and thickness for better prints. Below I have listed five of the most popular designs and what I like and dislike about them. While these specific designs may not be available on the kit, or preassembled printer you are looking at, chances are that its extruder is based off of one of these designs.

Makerbot StepStruder - The current extruder offered from Makerbot is the StepStruder MK7 and is their second stepper motor extruder design. Instead of a plastic based thermal transition barrier, the StepStruder MK7 utilizes a built-in heat sink and fan to keep the filament cool until the heat chamber. The MK7 has a small flaw in earlier models, though. The plunger design that forces the filament into the feed gear wears quickly and will lose tension causing the filament to strip, and the operator will need to disassemble the extruder to fix the issue. The MK7 does feature interchangeable nozzles. A unique feature to the Makerbot extruder is that it uses the stepper motor to directly drive the filament into the hot end. This is suitable for 1.75mm filament, but I feel that it does not provide enough torque for larger 3mm filament and could result in missed steps if a hard section of plastic were to pass through.

Makergear Stepper Plastruder - The Plastruder design offered by Makergear is unique to this list because it features a gear reduced stepper motor that provides additional torque to feed filament into the hot end. While I still consider this style "Direct Drive", one could agree that the gear box actually makes it an indirect drive. Unlike the Makerbot StepStruder MK7, the Makergear Plastruder is a little bulky and will require a larger frame to move around in. Also unlike the MK7, this extruder design utilizes a plastic insulator between the hot end and the filament feed to prevent filament preheating that causes jams. The Makergear Plastruder features the Makergear GrooveMount HotEnd, which is similar to another hot end we will mention later. While it has a removable nozzle, I feel that its nichrome wire heating method is antiquated, messy and very unreliable. Replacing the nichrome when it burns out is not only a time consuming and complicated task, but it is quite difficult for a non-tech minded person to accomplish.

For the next three items on our list, I have chosen to only list the hot ends as each one uses a version of the Wades extruder which has been modified by users to fit their specific needs. This extruder carriage features a nema 17 stepper motor and 3D printed gears. I personally am a fan of the Greg's Wade Reloaded design that features a filament tensioning system that utilizes springs instead of rubber O-rings like the Makerbot MK7. This makes changing filament, and clearing out clogs much easier. My gears of choice are the Parametric Herringbone Gears by Scribble J.

Modified Wades Extruder with Arcol Hot End - Pictured above is one of the more popular hot ends that has become one of the go-to hot ends for those wanting to print exotic plastics such as nylon. The Arcol V3's machined aluminum cooling fins make it a good candidate for plastics requiring extreme temperatures because of their cooling ability, which prevents heat from sinking up to the filament feed. Heat is provided to the Arcol hot end via a power resistor. This method is far superior to the nichrome wire method used on the Makergear Plastruder and is easy and quick to change out in the event of a failure. The only drawback to using the Arcol hotend is that its nozzle is built into the heater block and is not interchangeable.

Reifsnyder Precision Works J Head - The J Head hot end was one of the very first hot ends that I fell in love with. Its machined design is able to dissipate excess heat while still being able to heat up enough to print high tem plastics. Unlike some similar designed hotends, the J Head is machined from a solid piece of metal, making it highly reliable, and long lasting. Like the Arcol, its only downside is that its nozzle diameter is fixed and cannot easily be swapped out. I personally know the guy behind the JHead and have discussed, at length, the decision to make the nozzle a fixed unit. The reasoning behind it was to create the lightest and strongest design possible. This allows for faster head travel and a longer lifespan.

Lulzbot Budaschnozzle 1.3 - This is by far the best hot end ever made in my opinion. It combines all of the awesome features on the Arcol Hot End that it was based off of, with the removable nozzle design of the Makerbot MK7. It is heated by a power resistor, and comes prewired for ease of installation. This is the same nozzle that I use on my personal 3D printer and I have not experienced a failure in almost 10 pounds of filament. The Budaschnozzle 1.3 is designed to print so-called harder to print plastics such as nylon and wood infused plastics. When combined with a Greg's Wade Reloaded and a set of herringbone gears you get an extruder that is as robust as a tank and is capable of fine prints down to the sub 0.25mm range.

Print Platform / Bed Types

The print platform or "bed" is just as important as the extruder. The material it is made out of, is it heated, and is it easily adjustable are all factors you need to take into consideration when choosing which printer is right for you as the bed type will determine how easy it is to print different materials. Regardless of which type of print bed you are using, it is considered good practice to cover the bed in some sort of high temperature tape. Kapton or Polymide tape is the norm, but I feel that 3M's PET based tape is the better product, as it last longer and resists acetone.

Some print beds utilize a fixed mounting solution while others are adjustable with a spring under each mounting bolt, making fine tuning very easy. I feel that bed adjustability is a major factor in achieving good print quality. Leveling the bed by tweaking each corner's height is the easiest way to get a perfectly flat surface.

Another factor to consider is that some print beds are stationary and the print head moves in all axis. Other designs move the print bed on the x and y axis with the extruder moves on the z axis. I do not feel that either of these designs are better than the other and that choosing a heated bed over a non-heated bed is the more important factor.

Non-Heated - A non-heated bed is something you should avoid unless your budget simply will not allow for the extra cost. Non-heated beds can be made out of several different materials, with the most popular being laser etched acrylic. This type of bed makes controlling print warping almost impossible. When using a non-heated bed, generally you would want to print using a Raft which broadens the contact surface between the print and the bed. Rafts are hard to remove and waste filament. My advice is to spring for the heated bed and never look back.

Heated Bed - The heated bed revolutionized the quality of prints coming out of hobbyist level 3D printers. It reduced warping and splitting by as much as 90% on some printers and improved adhesion tenfold. With the introduction of heated beds we were also able to move to raft-less printing, which improved bottom surface quality. Heated beds are usually topped by a 1/8-inch thick sheet of borosilicate glass that is covered in a high temperature tape. Heated beds often see temperatures as high as 140c and are usually made from a simple PCB with a maze of traces etched onto the surface to create resistance.

Electronics

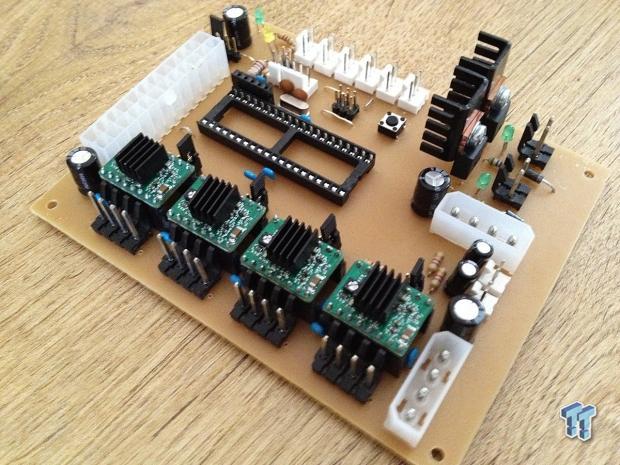

The electronics that control your 3D printer are just like your central nervous system. They take the input from your computer, and tell the printer's mechanical systems what to do. Most of the popular electronics out there today are based off of Arduino and some even come as shields that you place on top of an Arduino Mega. Below are four of the current most popular controller boards that are being used on the industry leading hobbyist level printers.

RepRap Arduino Mega Pololu Shield - AKA "RAMPS" for short, this board is by far the most widely used 3D printer controller at the moment. Version 1.4 of RAMPS features controls for up to three heated assemblies (one bed and two extruders), connections for up to six extruders, and can be powered by any 12V power source that has a minimum current rating of 20 amps or more. DIYers often use old 300w power supplies salvaged from PCs to power the board. RAMPS is truly a modular controller board. Unlike some designs, the Pololu stepper motor drivers are plugged into header pins individually for ease of maintenance should one burn out. In addition, the entire board is replaceable should something fail and not kill the Arduino it is plugged into.

Sanguinololu - Aimed more at the budget friendly 3D printers, the Sanguinololu is a simple single board design that is based around the Sanguino which is an Arduino compatible development board created by one of the founders of Makerbot. Other than a single surface mount FTDI 232 chip, the entire board is a through hole design, which makes hand soldering it a breeze. Like RAMPS, it features headers for modular Pololu stepper motor drivers, but is only capable of running five stepper motors. The Sanguinololu is also limited to just two heated assemblies so a second extruder is out of the running. Over the years I have built about 25 of these boards for customers, friends and myself and not once have I ever seen one fail.

RepRap Gen 7 - The Generation 7 Electronics from the RepRap project are designed to be a completely Do-It-Yourself project. The PCB is design is single sided which makes etching it at home quite easy. All of the components are through hole for easy soldering. Like RAMPS and Sanguinololu, Gen 7 utilizes the modular stepper drivers from Pololu for ease of maintenance. Gen 7 cannot be purchased and if you chose to go this route you most certainly will need to be mechanically and electronically minded. It is advised to visit the Gen 7 RepRap Wiki page as well as joining the RepRap IRC Discussion on what is needed to build a Gen 7 board.

RAMBo - A fairly new entry into the 3D printer controller board arena is the RAMBo, which was designed by Johnny R. from Ultimachine. It is the only all-in-one "RepRap motherboard" that I am comfortable recommending at the moment because of the standards in which it was designed to. RAMBo features an Arduino MEGA compatible Atmega2560 and Atmega32u2 processors are compatible with all RAMPS class firmwares. It houses five on-board stepper motor drivers, five PWM outputs, and can handle up to three heated assemblies through three independent power rails. If there were a Cadillac model of 3D printer electronics, this would be it.

Firmware Packages

3D printing software is a very dynamic topic that I could spend hours and an entire article covering. For the purpose of this guide, I will just hit on the basics and what I feel is the best software for your 3D Printer. There are basically three main firmware packages that are in use today. Each works basically the same, but is tailored to fit certain types of 3D printers better.

Marlin/Sprinter - This is the default, go-to firmware if you are running a current generation RepRap derived 3D printer such as a PrintrBot, Lulzbot, Mendel, Prusa Mendel or Mendel Max. It works out of the box. Marlin features a few innovative features such as "Look Ahead" which keeps up the speed of the print head when approaching and turning corners. It is also able to utilize an SD Card and LCD for PC-less printing. Marlin / Sprinter is compatible with RAMPS, Generation 7 and Sanguinololu as well as several other 3D printer electronics packages.

Teacup - Teacup avoids C++ in favor of plain C, uses 100% integer math and works very hard to minimize/eliminate long math operations in interrupt context. As a result, it offers optimum precision over a wider range (integer = 31 bit, float = 23 bit), it's only half the binary size of similarly featured firmwares, runs on about any ATmega microcontroller existing, including the USB-equipped ones, and can still be tailored to run on controllers as small as the ATmega168. It runs fine on RAMPS, Generation 7 and Sanguinololu as well as several other 3D printer electronics packages.

Sailfish - Sailfish is the firmware of choice for Makerbot's current generation 3D printers and is billed as being faster than Marlin. Sailfish builds on Makerbot's Gen4 and MightyBoard firmwares using acceleration derived from the RepRap firmware Marlin. It also adds a number of original improvements, including the asymmetric JKN Advance algorithm, the Yet Another Jerk jerk control, and use of fixed point computations for speed. Previous to Sailfish 4.0 for Thing-O-Matics and Cupcakes and Sailfish 6.2 for The Replicator 1, Sailfish was known as Jetty Firmware.

Control Software and Final Thoughts

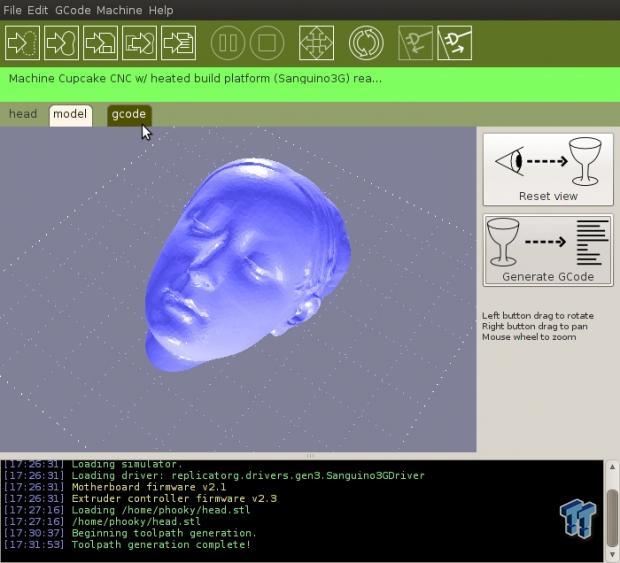

Control Software

Rounding our list of what makes up a 3D printer is control software. This is the programs that slice up our 3D files into layers and spit them out to the machine in a language it can understand. I am going to cover two slicing programs and three control programs below. The important thing to remember is that all of these work well and you will need to figure out what works best for you.

Slicing Programs

Slicr - Slic3r a tool that converts a digital 3D model into printing instructions for your 3D printer. It cuts the model into horizontal slices (layers), generates toolpaths to fill them and calculates the amount of material to be extruded. Slic3r is bundled with the most important host software packages: Pronterface, Repetier-Host, ReplicatorG and has been supported/funded by almost all the main 3D printing companies in the world. Slicer works very well and is what I use on my printer. My only issue is that it's estimation of print time and filament used is a bit overestimated, but that is something I am willing to live with.

Skeinforge - Skeinforge is another slicing program that is mostly used in the Makerbot line of printers, and utilizes Python scripts to convert your 3D model into G-Code instructions. It takes the settings you set and uses them to turn your 3D model into a toolpath for your 3D printer. This toolpath is generated as GCode, which is then converted to .x3g or .s3g before it's sent to your bot. You can set things like layer height and extrusion temperature quite easily, but Skeinforge has a lot more settings behind the scenes, and you can edit these manually by opening up the Skeinforge interface. Skeinforge is pretty complicated, and it can be very confusing, but getting familiar with even a few of the settings can let you do all kinds of cool things with your prints.

Print Control Programs

Printrun / Pronterface - Printrun consists of printcore, pronsole and pronterface, and a small collection of helpful scripts. Printrun has become the default control software for 60 percent of all enthusiast level 3D printers due to its powerful yet simple to use interface called Pronterface. It is pre-packaged with Slic3r and is able to control all RepRap and Makerbot based 3D printers. I have been using it since its inception and feel that this is the best control software currently on the market. It is entirely open source and is freely available for download from Github.

Replicator G / Makerware - These are the control software offered by Makerbot. Replicator G is very similar in functionality to Pronterface, but lacks some of the more in-depth control that Prinrun features. It has been replaced by Makerbot's next-generation software, MakerWare. MakerWare features a new slicing engine called MakerBot Slicer which is said to be up to 20 times faster than Skeinforge. MakerWare lets you drop as many models as you want into the virtual build space, and its simple yet powerful interface lets you move, rotate and scale your models easily. When it comes time to choose your print settings, we've refined the process while still leaving the control in your hands. This software is closed source and can only be used on MakerBot printers unless you are up for some extensive hacking.

Repetier-Host - A fairly new comer to the 3D printing game, Repetier is a redesign of what slicing and control software should be. Repiter is essentially an entire package. To run it you will need to download and install the Repetier firmware, and then install the host client to your PC. With the host software you can easily adjust the position of the object to be printed in relation to your print bed, as well as auto position items. I have been hearing a lot of good things about Repetier in the RepRap IRC channel as well as from friends in the 3D printing groups I frequent. For the moment I am sticking with PrintRun as I have my printer dialed in perfectly and do not want to change anything.

Final Thoughts

That basically covers what I consider to be major components of a 3D printer. There are other minor parts that you could consider like belt types, pully sizes, and ACME rods verses threaded rods, but for the most part, they all perform in the same ballpark, and are easily upgradeable in the future. I really just wanted to touch on what I feel are the most important things to pay attention to when you consider investing in a 3D printer.

In my next installment we are going to take a look at several kits, and preassembled 3D printers that are currently available on the market. I am going to do my best to compare them and offer my take on the pros and cons of each.

Finally we will look at the pricing point of each kit and I will make my pick for the best 3D printer kit and best preassembled 3D printer. Keep an eye out right here at TweakTown in the coming days for Part 2 of our 3D Printers Buyers Guide.

United

States: Find other tech and computer products like this

over at

United

States: Find other tech and computer products like this

over at  United

Kingdom: Find other tech and computer products like this

over at

United

Kingdom: Find other tech and computer products like this

over at  Australia:

Find other tech and computer products like this over at

Australia:

Find other tech and computer products like this over at  Canada:

Find other tech and computer products like this over at

Canada:

Find other tech and computer products like this over at  Deutschland:

Finde andere Technik- und Computerprodukte wie dieses auf

Deutschland:

Finde andere Technik- und Computerprodukte wie dieses auf